Custom Digitizing for Embroidery: Customized to Your Demands

Custom Digitizing for Embroidery: Customized to Your Demands

Blog Article

Grasping the Needlework Digitizing Process: Your Ultimate Guide

Needlework digitizing is a meticulous craft that needs accuracy and competence to translate elaborate styles right into digital formats for maker needlework. As artisans start this journey to understand the needlework digitizing process, an extensive understanding of the essentials sets the structure for quality. However, beyond the fundamental expertise exists a realm of sophisticated software program, specialized devices, and nuanced techniques waiting to be checked out. By diving right into the nuances of digitizing, one can unlock a world of creative possibilities and elevate their embroidery jobs to new heights.

Comprehending Needlework Digitizing Fundamentals

Embroidery digitizing fundamentals develop the structure upon which complex styles are equated into machine-readable formats for accurate stitching. This initial step in the embroidery digitizing process is vital for ensuring that the last embroidered item is a loyal depiction of the original design. Understanding needlework digitizing essentials includes grasping crucial concepts such as stitch types, stitch direction, thickness, padding, and draw payment.

Stitch types play a vital role in determining the aesthetic and textural result of the embroidered style. By picking the proper stitch type, whether it be satin, fill, or running stitch, digitizers can accomplish the desired result and improve the total top quality of the embroidery. Additionally, sew instructions influences the flow and dimension of the style, while density figures out the spacing and protection of the stitches.

Furthermore, padding stitching provides security to the design by safeguarding the textile and avoiding distortion during the embroidery procedure. Pull payment is an additional necessary factor to consider to counteract the natural propensity of material to agreement when sewn. Understanding these needlework digitizing basics is fundamental for producing professional-quality embroidered products.

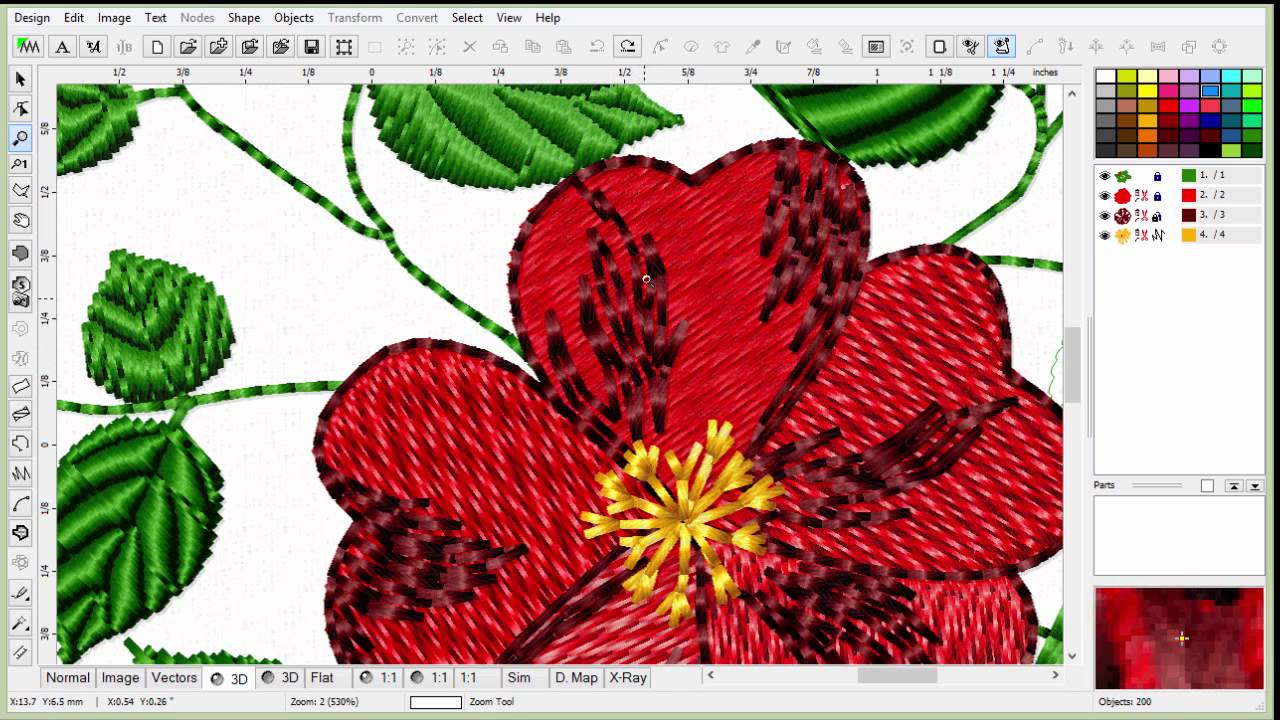

Picking the Right Digitizing Software Application

Choosing the suitable digitizing software is an essential decision that significantly impacts the performance and top quality of the needlework digitizing process. Digitizing for Embroidery. When picking the right digitizing software program, it is necessary to think about aspects such as the complexity of styles you plan to create, the user-friendliness of the software, the level of client assistance supplied, and the compatibility with your embroidery equipment

There are different digitizing software program alternatives available in the marketplace, varying from standard programs for newbies to advanced software for professional digitizers. Some popular choices consist of Wilcom EmbroideryStudio, Hatch Needlework Software Program, and PulseID. These software program plans use a vast variety of tools and functions to help you produce intricate designs easily.

Before making a decision, it is recommended to explore the various software program choices with complimentary trials or demos to determine which one finest suits your demands. In addition, checking out reviews and looking for referrals from skilled digitizers can offer valuable understandings into the strengths and weak points of each software (Digitizing for Embroidery). By carefully reviewing your demands and comparing the attributes of different digitizing software, you can make an educated choice that boosts your needlework digitizing workflow

Digitizing Tools and Strategies

Optimizing Layout Setup for Embroidery

Grasping the complexities of style settings is fundamental in achieving ideal outcomes in the needlework digitizing process, building upon the foundation laid by recognizing digitizing devices and methods. When enhancing style settings for needlework, it is vital to take into consideration variables such as stitch kind, thickness, padding, draw settlement, and registration. Stitch kind choice affects the overall appearance and feeling of the design, with options like satin, fill, and running stitches supplying various textures and results. Thickness over here describes the spacing and density of stitches, impacting the design's insurance coverage and longevity. Appropriate underlay sewing supplies stability and protects against material distortion, especially for intricate styles or on stretchy products. Pull settlement changes for fabric stretch throughout sewing, making sure accurate design duplication. Enrollment settings straighten different components of the design properly, preserving total design honesty. By fine-tuning these design setups, embroiderers can enhance the high quality and precision of their stitched creations.

Troubleshooting Common Digitizing Issues

When encountering typical digitizing issues during the needlework procedure, it is vital to recognize the source and implement efficient options without delay. One common issue is stitch thickness issues, where stitches may be also dense, triggering the material to tighten, or too sporadic, causing voids in the design. Changing the stitch density setups in the digitizing software program can help fix this problem.

An additional frequent challenge is thread breaks throughout the needlework procedure. This can occur due to different investigate this site factors such as incorrect stress settings, boring needles, or utilizing low-grade string. Making certain correct upkeep of the embroidery maker, including normal needle changes and stress changes, can decrease the event of string breaks.

Moreover, design registration mistakes can cause misaligned components within the needlework layout. Examining the design alignment in the digitizing software application and making required modifications before stitching can help in preventing this concern. By resolving these usual digitizing concerns immediately and successfully, you can make sure a smoother needlework process and top notch completed products.

Verdict

Finally, understanding the embroidery digitizing process calls for a strong understanding of the fundamentals, the best choice of software, and expertise of devices and methods. Enhancing design settings and troubleshooting common digitizing concerns are critical actions in making sure high-grade needlework outcomes. By following these actions faithfully, one can accomplish precision and performance in the digitizing process.

Report this page